Many customers are curious about the industry standards involved in producing electric razors. Among them are well-known brand owners, Amazon sellers, small business entrepreneurs in the men’s grooming industry, and professional buyers of beauty and personal care devices. As the world’s leading wholesale electric shaver manufacturer, Huux is here to share key industry standards and insider knowledge with you to help you choose the right electric razor for your business.

1. What Are Industry Standards for Electric Shavers?

There is a plethora of industry standards for electric shavers, and they essentially cover every aspect of the product life cycle, including classification, technical prerequisites, testing procedures, inspection guidelines, labeling, packaging, transportation, and storage considerations. The standards shared in this article are applicable to all electric shavers manufactured in China, regardless of whether they are powered by alternating current, rechargeable batteries, or dry batteries. Therefore, they are a reliable reference for any potential buyers who are seeking to maintain the highest standards in the design, production, and utilization of wholesale electric razors.

Each standard will be explained in detail in the paragraphs below.

2. Basic Technical Requirements for Electric Razors

Before we dive into the specifics of how tests are conducted to ensure electric razors meet their standards, here are some fundamental technical requirements that you need to know:

- Application Environment: Electric shaversare generally designed for use in a general indoor setting or other similar environments. Therefore, it should be used in areas where there is no risk of explosive mediums, corrosive metals, gases that can damage insulation, or conductive dust. The ambient temperature should be maintained between 0°C and 40°C.

- Safety Requirements: Electric shavers shall comply with the provisions of GB 4706.1 (General Safety Requirements for Household and Similar Electrical Appliances) and GB 4706.9 (Specific Safety Requirements for Electric Shavers, Hair Clippers, and Similar Appliances).

- Start Performance: The electric shaver shallstart smoothly at 0.9 times the rated voltage.

- Temperature Rise of the Foil: The temperature rise of the electric shaver’s foilshall not exceed 30K, as tested in accordance with the method specified in section 4.2.

(Note: It is generally believed that when the temperature rise of the foil exceeds 30K, it will make users feel a scalding pain when it contacts the skin.)

- Hardness of the Foil and Blades: Manufacturers are required to conduct this test on their blades, in which the hardness of the electric shaver net and blade shall comply with the provisions specified in Table 1.

| Blade Type(Divided by hardness value/HV) | Carbon Steel | Stainless Steel, Electric-cast Alloy |

|---|---|---|

| Shaver knife net | 543 | 400 |

| Shaver blade | 664 | 400 |

| Trimmer blade | 664 | 400 |

Table 1: Hardness of the knife mesh and the blade

- Foil Roughness: The resulting outer surface roughness of the shaver from testing shall not be greater than Ra 0.40. (Note: This requirement does not apply to surface mesh with densely arranged convex and concave shapes.)

- Sharpness: Sharpness tests are conductedaccording to the method specified in the following section of this article. When using #612 nylon wire with a diameter of 0.1 mm, the wire should be cleanly cut without halting. The curling root rate should also be less than 15%.

- Noise: When the electric shaver works, the foiland the blade should be evenly fitted together with friction, and the sound should be harmonious, with no impact or irregular noise. Relevant noise tests should be conducted, and the noise and sound power level of the electric shaver shall not be greater than 75 dB during those experiments.

- Power PlugDurability: After the plug pin is rolled out during testing, the front end of the pin should not shrink when bearing a force of 60 N. Additionally, after the pin is introduced and indented 2000 times, it shall not be abnormal and completely connected, and the connection formed by the pin must remain secure and fully operational.

- Time Between Failures: The total fault-free working time shall not be less than 60 hours.

- Working Hours After Each Full Charge: The cumulative working time for rechargeable electric shavers shall not be less than 25 minutes. For dry battery-powered electric shavers, the cumulative working hours after battery replacements shall not be less than 60 minutes.

- Appearance Requirements: Plastic and rubber wood parts must be devoid of any visible flaws or sharp burrs. All metal components (except for the razor’s shaving head) should possess qualities like corrosion resistance. Coatings must be smooth, even, and free of stains, watermarks, hemp points, pinholes, bubbles, peeling, or discoloration. Similar defects such as protrusions and cracks are also unacceptable.

- Structural Requirements: Electric shavers shall be equipped with a protective cover or similar protective structures in order to safeguard the foil.

3. The Actual Testing Process: Experimental Methods for Electric Shavers

In this section, we will be providing you with an in-depth analysis of how experiments are conducted for electric shavers that are required to meet industry standards, and an overview of the standards for these tests as well. Take a closer look at the standardized testing methods below.

3.1 General Test Conditions

- Unless otherwise specified, the test shall be conducted under indoor ambient conditions of (20 ± 5) ℃.

- The accuracy of electrical measuring instrumentsused shall be no less than 0.5 class during type tests, and its accuracy shall not be less than 1.0 class upon factory tests.

- The rated current of the DC voltage stabilizing power supply for the test shall not be less than 1A, and the voltage regulation accuracy shall not be less than 2%.

- Samples must be tested in the operatingstate specified in the product manual.

- The test power supply shall be consistent with the power supply specified in the product. When the product has multiplepower supplies, the relatively unfavorable one should be selected.

- Prior to and during testing, the blade should be lubricated with an adequate amount of light oil.

- Safety tests shall be conducted per GB 4706.1 and GB 4706.9.

- The performance test should commence by initiating the electric shaver three times, adhering strictly to the voltage specifications outlined in the preceding chapter. Each start should occur only after the motor has fully halted.

3.2 Foil Temperature Rise Measurement

To assess how quickly the temperature rises on the foil, apply 1.06 times the rated voltage to the electric shaver. Operate for 10 minutes, then measure the maximum temperature rise on the foil’s surface.

3.3 Hardness Test of Knife Foil and Blades

In this test, it is recommended to use a Vickers hardness tester for evaluating the hardness of knife nets and blades. Manufacturers will select three points near the blade edge and three points on the upper and lower blade teeth, and calculate the average value of all six test points.

3.4 Foil Surface Roughness Testing

The roughness of the foil surface shall be measured using a roughness tester or compared with standard roughness samples.

3.5 Sharpness Test

After the electric shaver is fully charged, disconnect the power supply, set the razor to the strongest mode, and our sharpness test will start from there.

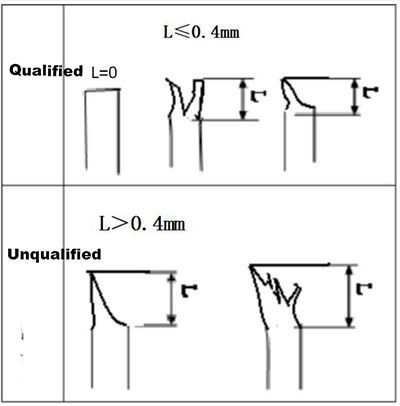

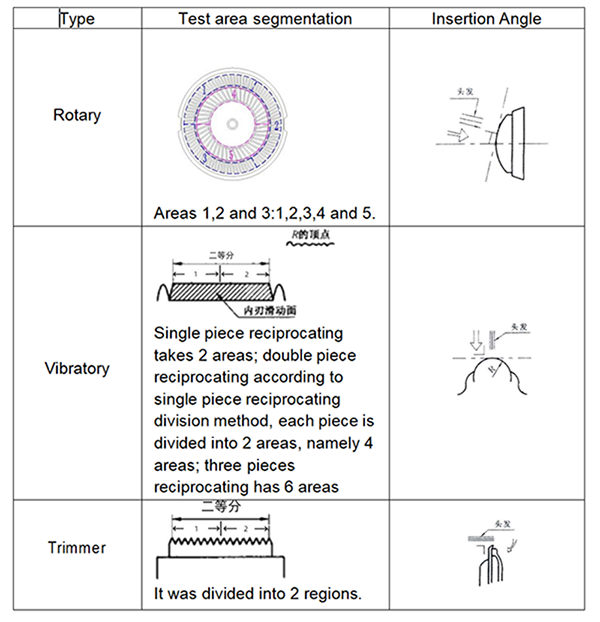

Perform the test using PA 612 nylon filaments (0.1 mm). Arrange 10 filaments tightly (<1 cm wide), 4–6 mm from the tip of the bundle. Then, insert the bundle slowly into the test zone at ~1 mm/s (see Figure 1 & 3). Stop the trial 3 seconds after contact. Examine under a 30× microscope and record the number of coiled roots (K). The curling root number rate is calculated according to the following formula:

Rroll up=K / (region number N * 10) x 100%

where K = number of curled filaments, N = number of test areas.

Repeat the trial three times, and take the average value. (Note: Uncut filaments are excluded from curl count.)

Figure 1 Schematic diagram of nylon silk placement

Figure 2 Schematic diagram of nylon coil

Figure 3 Schematic representation of the sharpness test area

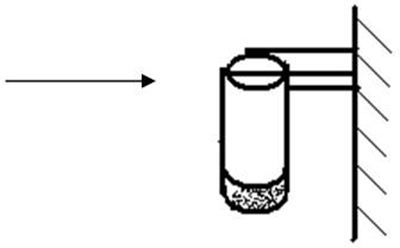

3.6 Power Plug Pin Tests

For the axial force test, a 60 N force is applied to the axis direction of the front end of the two pins, as shown in Figure 3, for 2 seconds.

As for testing its durability, pins undergo extension-retraction cycles 10-20 times/min (one push is called once).

Figure 2 Schematic diagram of nylon coil

3.7 Noise Measurement

The measurement is assessed via auditory and tactile evaluation by test personnel. Conducted per IEC 60704-2-8, the test uses a hemispherical measurement surface radius of 1m.

3.8 Measurement of Mean Time Between Failures (MTBF)

For AC shavers, apply rated voltage and keep the shaver running in cycles where it is turned on for 5 minutes, and then closed for the same amount of time. Rechargeable shavers are to undergo the same procedure after a full charge cycle. As for dry battery shavers, use nominal voltage DC power and operate the device under the same 5-minute cycle, but the foil needs to be lubricated daily,

If an electric shaver passes the industry standards, it should operate without failure before the total running time reaches 60 hours.

3.9 Operating Time per Full Charge

For Rechargeable Shavers: After a full charge/discharge cycle, disconnect the charging cable, and let the device stand idle for 1 hour. Adjust the shaver to the strongest operating mode and run it in 5 minutes on/5 minutes off cycle. Continue the process until the electric shaver shuts down, signaling the end of this experiment. Record the cumulative runtime and write it down in minutes.

For Dry Battery Shavers: Power the shaver with an external DC source matching the battery voltage. Operate the device by switching to the strongest operating mode and running it in 5 minutes on/5 minutes off cycle. Monitor the electricity consumed by the electric shaver during this process. End testing when the energy consumption equals the reference battery capacity, and calculate its cumulative runtime.

4. After Testing: Inspection Regulations

4.1 Inspection Rules for Electric Razors

The electric shaver must undergo testing in accordance with this article, as well as GB4706.1 and GB4706.9 standards. Mass production can only commence after a formal appraisal has been successfully completed. Products are permitted to leave the factory solely after the manufacturer has successfully passed the factory inspection. The inspection process for the electric shaver consists of two parts: factory inspection and type testing.

4.2 Visual & Structural Inspection

Visual and structural inspections are conducted via tactile and visual examination. When conducting a structural inspection for electric shavers, visual inspection plays a crucial role. This involves carefully examining the shaver’s structural components for any signs of damage, wear, or defects. Inspectors should look for cracks, loose parts, or any other visible indications of structural issues.

4.3 Mandatory Inspection Items

Mandatory factory inspection items, requirements, and methods are listed in Table 2.

| Order Number | Test Item | Technical Requirement(Chapter) | Experimental Method(Chapter) | GB4706 Chapter | Classification of Defects – Causing Death | Classification of Defects – Light |

|---|---|---|---|---|---|---|

| 1 | Cold-state electrical strength examine | √ | √ | |||

| 2 | Start performance test | √ | √ | √ | ||

| 3 | Noise check | √ | √ | √ | ||

| 4 | Appearance and structure inspection | √ | √ | √ | ||

| 5 | Product logo | √ | √ | |||

| 6 | Product package | √ | √ |

Table 2 Compulsory inspection items for factory inspection

4.4 Sampling Items

Manufacturers shall also conduct batch sampling per Table 3. Sampling plans (batch size, AQL, etc.) shall be agreed upon by manufacturers and purchasers, following GB/T 2828.1.

(Note: The unqualified electric shavers with defects in the factory inspection shall be submitted again for re-inspection after repair and rework, and can only leave the factory after passing the re-examination.)

| Order Number | Test Item | Technical Requirement(Included) | Experimental Method(Included) | GB4706.9 Chapter | Classification of Defects – Causing Death | Classification of Defects – Light |

|---|---|---|---|---|---|---|

| 1 | All required items for factory inspection | See Table 2 | See Table 2 | See Table 2 | See Table 2 | See Table 2 |

| 2 | Noise | √ | √ | √ | ||

| 3 | Use in to connect the power supply | √ | √ | √ | ||

| 4 | Appearance and structure inspection | √ | √ | √ | ||

| 5 | Working hours after each full charge | √ | √ | √ | ||

| 6 | Leak current and electrical strength | √ | √ |

Table 3 Sampling inspection items of factory inspection

4.5 Type Testing

Type testing is required when one of the following situations occurs:

- a) New product certification;

- b) Annual production audit;

- c) Post long-term production halt;

- d) Major design/material/process changes affecting performance;

- e) Significant deviation from previous type test results;

- f) Requested by national quality authorities.

The sampling shall be conducted as per GB / T 2829. Samples shall be drawn from factory-approved batches, with ≥3 units per group (performance/safety). If any of the samples fails in the test, double the amount of samples taken for the re-inspection. Persistent failure voids certification and halts production until corrective actions are validated.

Type-tested products shall not be sold as regular goods.

4.6 Standards on Marking, Packaging, Transportation, and Storage

- Marking:Each electric shaver shall bear a durable nameplate which shall clearly mark the contents of GB 4706.9-2008 Clause 7.1. For appliances powered by rechargeable batteries, clause 7.1 of GB 4706.1-2005 Annex B shall also be labeled. Individual packaging shall comply with GB/T 5296.2.

- User Manual: Each shaver shall include a manual per GB/T 5296.2, GB 4706.1, and GB 4706.9.

- Packaging: The packaging of electric shavers shall meet the requirements of GB / T 1019.

- Transport: During the transportation process, rain, damp, and violent collisions are strictly prohibited.

- Keep in storage: Electric shavers should be stored in a ventilated, dry environment, and the box should be kept ≥150mm above ground, away from corrosive chemicals.

At Huux, our products not only align with but exceed industry standards. Quality control is a top priority in the manufacturing of custom beauty and personal care devices. To ensure the highest level of excellence, we implement the Six Sigma quality management system in addition to mandatory regulatory testing and certifications. Every product undergoes a thorough inspection before shipment to guarantee safety, performance, and customer satisfaction.

If you’re looking for a reliable wholesale manufacturer to help you create a bestselling product for your beauty or personal care brand, Huux is the ideal business partner you can count on. Contact us today by sending an email to info@huux.com to learn more about our OEM/ODM services and how we can support your business growth. We promise you won’t be disappointed.