In the competitive personal care and hair styling industry, manufacturers face increasing pressure to deliver products of impeccable quality. At Huux, a leading manufacturer of hair styling tools, we understand that the key to creating high-performance hair tools lies in the precise control of our production environment. This is why we have invested in advanced clean room facilities, a must-have for any manufacturer that wants to stay at the forefront of its industry.

In this article, Huux will take you on the journey of exploring the concept of dust-free clean rooms, their varying levels, and the critical role they play in ensuring the highest product quality. Keep reading to find out why Huux has built Class 5 clean rooms, how they benefit customers, and how this decision forms the foundation of our commitment to excellence in personal care appliance manufacturing.

What is a Dust-free Clean Room?

A clean room is a highly controlled manufacturing environment designed to minimize the presence of airborne particles, microorganisms, chemical vapors, and other contaminants that can compromise the quality and functionality of products. Clean rooms are categorized by how strictly the number and size of particles per cubic meter of air are regulated (For more information on how clean rooms are categorized, click here to skip to this section of this article: Different Levels of Dust-free Clean Rooms).

These environments are essential in industries where even microscopic levels of contamination can lead to performance issues, defects, or safety concerns. In the personal care industry, where precision, safety, and reliability are critical (especially for electrical hair tools), clean rooms are increasingly becoming a cornerstone of advanced manufacturing processes.

Many factories claim to operate in clean rooms or attempt to blur the distinction by advertising so-called ‘dust-free workshops,’ but these often fall short of the stringent standards that true clean rooms require. A dust-free workshop doesn’t always equal a clean room. If a manufacturer’s “Dust-Free Clean Workshop” meets certain ISO Cleanroom Standards (e.g., ISO 14644-1 Class 5–8), then calling it a “Clean Room” is appropriate and professional. If a facility is not strictly controlled according to cleanroom standards and is only relatively cleaner than a normal workshop, then it should be strictly referred to as a dust-free workshop, or other terms such as “Controlled Environment Room”. We are proud to say that Huux’s manufacturing environment meets the standards for an ISO Class 5 clean room and is bound to give you an unparalleled wholesale experience.

How Clean Workshops Work

Clean rooms operate under rigorous conditions to ensure an ultra-sterile environment, which is essential for manufacturing precision products like Huux’s high-performance hair tools. Take a look down below at how clean rooms function to maintain manufacturing quality:

- Air Filtration: We’ve mentioned that clean rooms are essentially environments that keep any impurities out of the production process. To achieve this goal, these workshops use HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters to remove airborne particles as small as 0.3 microns. These filters are integral to ensuring that the air circulating within the clean room is free of dust, pollen, bacteria, and even microscopic fibers that could interfere with the production process. In a non-ideal manufacturing environment, air would contain millions of particles that could settle on sensitive components, but in a clean room, these particles are almost entirely eliminated.

- Pressure Differentials: Dust-free clean rooms maintain positive or negative air pressure, depending on their use and application. In a positively pressured clean room, air constantly flows outward through controlled exits when doors are opened, preventing unfiltered external air from flowing in. This is crucial in preventing outside contaminants from entering the room. For Huux, a manufacturer that produces hair tools with sensitive electronic and heating components, positive pressure ensures that the products manufactured are safe from external impurities.

- Environmental Control: Aside from particle management, clean rooms are rigorously regulated in terms of temperature, humidity, and other environmentally induced factors. In the case of electronic beauty tools, temperature control is critical in preventing the buildup of static electricity, which can damage electrical components in hair straighteners, curlers, and dryers. Humidity control is equally important because excess moisture in the air can interfere with the assembly process, affecting adhesives, coatings, or causing corrosion on metal parts. At Huux, we ensure that all these variables are finely tuned to create the ideal conditions for manufacturing high-precision hair tools.

- Personnel and Protocols: Even the people who work inside clean rooms must follow strict protocols to minimize contamination. Workers must wear specialized clean room garments (such as coveralls, gloves, masks, and shoe covers) designed to reduce the release of particles from clothing or skin. Every movement within a clean room is measured and controlled to prevent any unnecessary stirring of air, which could cause particles to settle on products or surfaces. This is especially critical in the personal care industry, where even a stray hair or fiber can damage or reduce the reliability of sensitive heating elements or electronic circuits.

Dust-free Clean Room Personnel

Different Levels of Dust-free Clean Rooms

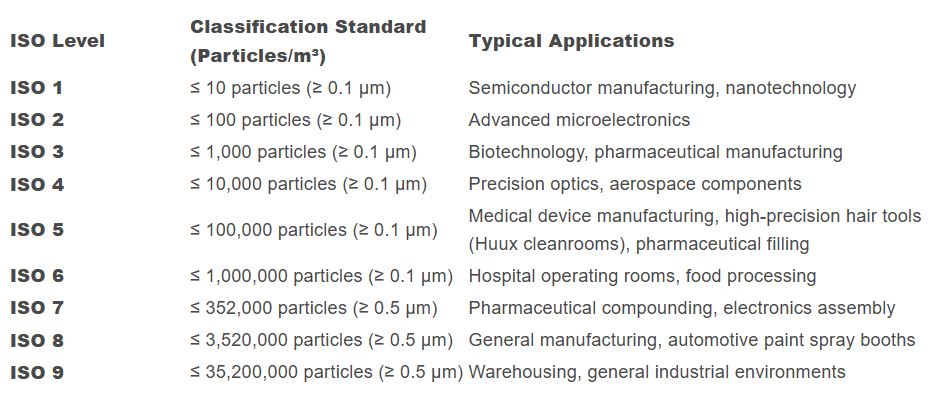

Clean rooms are classified by the level of cleanliness required, which is determined by the number and size of airborne particles allowed per cubic meter of air. The ISO classification system is the most widely recognized classification system for clean rooms, and it defines cleanliness based on the allowable number of particles of different sizes (measured in microns) per cubic meter of air. Each class targets specific industries and manufacturing processes.

ISO 14644-1 International Standard – Classification of Air Cleanliness

ISO Class 1:

This is the highest level of cleanliness for a clean room, and is typically used in semiconductor and microelectronics manufacturing, where even the tiniest particle could cause catastrophic failure. For example, in the production of integrated circuits and microchips, where components are measured in nanometers, any contamination can lead to defects that render an entire batch useless. Therefore, these types of manufacturing typically take place in ISO Class 1 clean rooms.

ISO Class 5:

ISO Class 5 is commonly used in pharmaceutical manufacturing, medical device production, and high-precision equipment manufacturing. This level of cleanliness is also ideal for producing sensitive electronic components and other products that require sterile conditions. Due to the product’s nature, even a small particle contaminating a heating element or temperature sensor could cause product malfunction or reduced performance.

In the personal care and hair styling industry, ISO Class 5 clean rooms are essential for processes like assembling tools with sensitive electronic parts, which typically include hair straighteners and curling irons. This is the same type of clean room that Huux utilizes in its daily manufacturing operations.

ISO Class 7:

This class is widely used in industries such as automotive manufacturing, aerospace, and basic electronics. It is less stringent than ISO Class 5, making it appropriate for industries where contamination is a concern but does not need to be as tightly controlled. Several well-known manufacturers and brands that utilize ISO Class 7 clean rooms include Venair Biotech, Sterling Industries, and CPC Worldwide.

ISO Class 9:

This is the least stringent classification for clean rooms and is often closer to the cleanliness levels of a standard office environment. ISO Class 9 clean rooms are primarily used in industries where contamination risks are minimal, such as warehousing or packaging of non-sensitive materials.

Why Huux Built Class 5 Clean Rooms

At Huux, we’ve selected ISO Class 5 clean workshops for key stages of our production process because they strike the perfect balance between cleanliness, practicality, and efficiency in manufacturing high-quality personal care products. These environments have provided us with the opportunity to provide premium-quality products to suppliers and businesses worldwide, and we are proud to introduce some of the benefits that come along with this decision:

Protecting Sensitive Electronics

Hair tools today incorporate increasingly complex electronic systems to ensure safety and performance. Features like automatic shutoff, adjustable temperature control, and digital displays rely on advanced electronic circuits and sensors. A single dust particle can interfere with these delicate systems, leading to operational failures or shortened product lifespans. An ISO Class 5 environment provides the cleanliness necessary to safeguard these critical components during production, reducing the risk of malfunctions.

Ensuring Heating Element Efficiency

The heating elements used in hair tools, whether ceramic or titanium, must heat evenly and maintain consistent performance over time. Contaminants such as dust, fibers, or even microscopic metal shavings from surrounding equipment can adhere to the heating elements during assembly and cause uneven heating or damage to the protective coatings. This can result in reduced performance or cause the tool to wear out faster. By manufacturing in ISO Class 5 clean rooms, Huux ensures that heating elements are assembled and tested in an ultra-clean environment, promoting product efficiency and durability.

Improving Safety Standards: Safety is a top priority in personal care products, especially for heated hair tools like curling irons and straighteners. Contaminants during the manufacturing process can cause overheating, short-circuiting, or premature failure of safety mechanisms, such as temperature sensors. A higher-level clean room helps to prevent these potential hazards by keeping the internal components free of impurities. This is essential to ensuring that the products we produce at Huux are not only high-performing but also safe for everyday use by consumers.

Preventing Aesthetic Defects: In addition to internal component reliability, the outer aesthetic of hair tools is also important. A consumer expects a product to both work well and be aesthetically pleasing. In an ISO Class 5 clean room, we can eliminate the risk of dust or particles marring the exterior finishes of our products during assembly or final inspection and achieve this goal. Whether it’s a high-gloss finish on a hair straightener or the metallic surface of a curling iron, maintaining a clean environment ensures flawless appearance and craftsmanship.

At Huux, we recognize that the quality of our personal care products starts with the environment in which they are made. By building and maintaining ISO Class 5 clean rooms, we ensure that every hair tool we produce is free from contamination, consistent in performance, and safe for consumers. Our dust-free clean rooms, combined with our cutting-edge equipment and rigorous testing protocols, make Huux the go-to OEM/ODM manufacturer for personal care and hair styling products. If you’re interested in ordering premium yet affordable wholesale products, leave an online message or email us at info@huux.com. We promise that you won’t be disappointed.